Introducing Bowman 3D

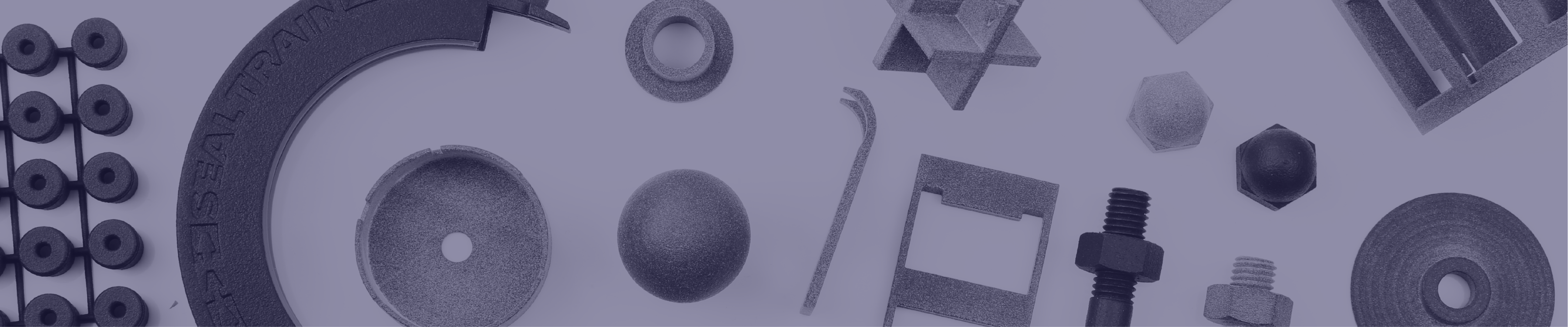

Our specialist additive production division uses industry leading 3D printing technology combined with lean manufacturing processes to produce 3D printed, production-volume parts that are traceable, reliable, accurate and verifiable.

Bowman 3D is an experienced and knowledgeable production partner for organisations all over the world. To find out more, visit the Bowman 3D website

MULTI JET FUSION

Bowman 3D uses powder bed fusion technologies to produce anything from one to tens of thousands of parts, using engineering grade material.

Our Multi Jet Fusion (MJF) 3D printer produces parts similar to the long-established Selective Laser Sintering (SLS) technologies by adding sequential layers of polymer powder and a fusing agent into a build chamber. It uses a high-powered heat source to selectively fuse areas of each layer together to form parts.

PRINTING MATERIALS

We focus our production on PA11, a highly versatile material that offers a higher elongation at break and a better surface finish compared to other printing materials. Being derived from castor oil, PA11 is more environmentally sustainable than other printing materials, and our economies of scale and lean efficiencies allow us to provide this superior material at a competitive cost, even compared to the usually cheaper PA12.

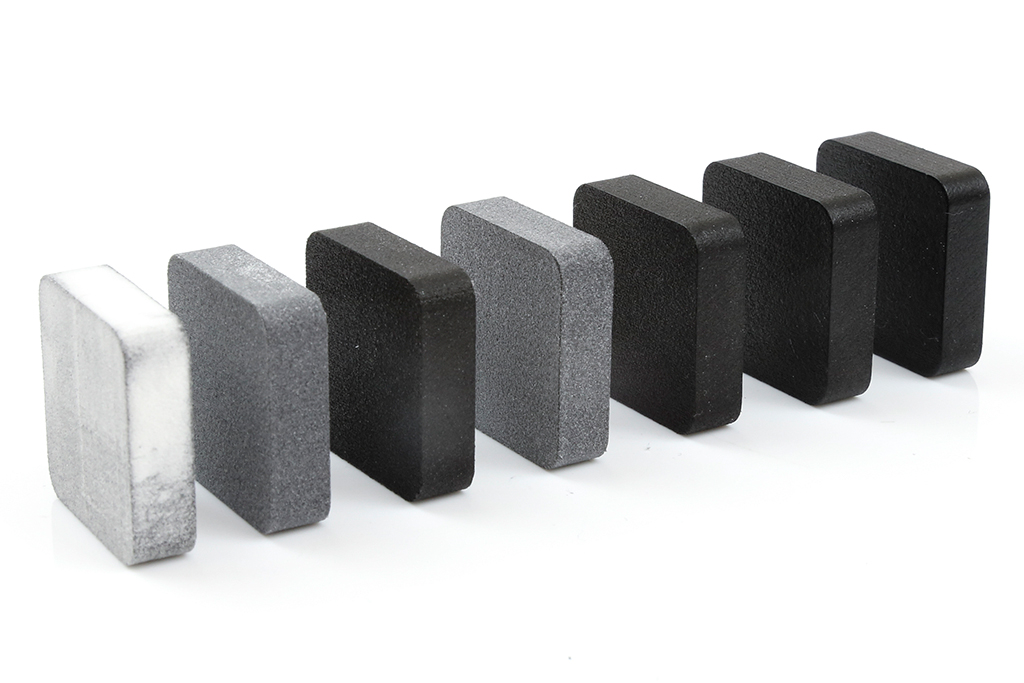

SURFACE FINISHES

Our specialist team will work with you to identify exactly which surface finish is right for your component, by explain the differences and demonstrating the benefits of each option.

There are a range of different surface finishes to choose from, including:

• Natural

• Dyed

• Vibro polished

• Vibro polished and dyed